|

|

|

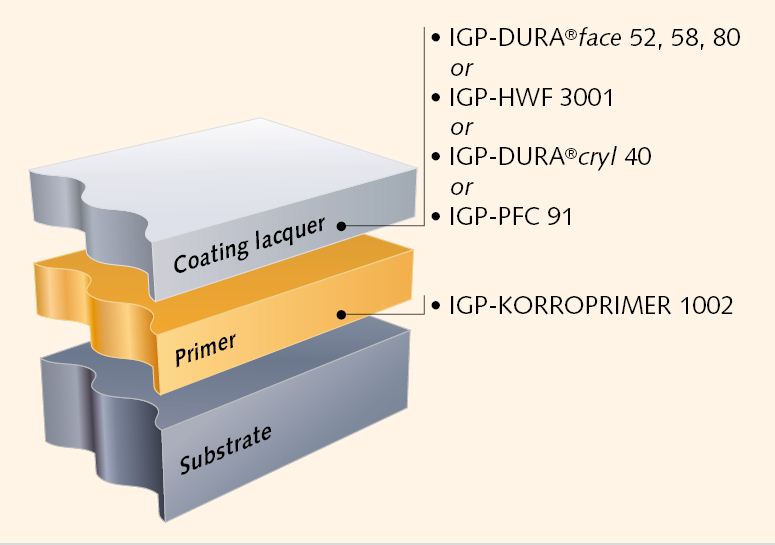

Our solution for permanent protection

Korroprimer is a priming powder

in 2-layer system with ultimate anti-corrosive effect.

A cost effective alternative

to galvanising, the anti-corrosion coating powder is based on epoxy resin designed for iron and steel substrates that can

also be used for priming chromatised aluminium to protect from filliform corrosion. This provides

an additional and special protective effect for use in the vicinity of the sea and in aggressive industrial climates.

A certified high performance anti-corrosive coating system. |

|

|

IGP-KORROPRIMER 1002

Product benefits

• good mechanical

properties

• excellent resistance to chemicals

• optimum adhesive power

• no toxic heavy metals

(e.g. zinc)

• variable over-coating (coating powder, painting, wet varnishing)

• economical in terms of

long service life and risk minimisation

Applications

• blasted steel (e.g. posts,

railings, handrails, parking meters)

• zinc-plated, chromatised steel (e.g. props of traffic guidance systems and

anti-noise walls)

• zinc-plated, blasted to reduce moisture diffusion

• machined zincor sheet metal for

protecting the non-zincplated spots and for covering the edges

• steel sheet (e.g. for occasional interior moisture

exposure, as primer for skeleton structures)

|

|

|

|

|

|

|

Product description

IGP-Korroprimer 1002 is an anti-corrosion coating powder based on epoxy

resin, designed for iron and steel substrates. The product can also be used for priming chromatised aluminium to protect from

filliform corrosion. This provides an additional and special protective effect for use in the vicinity of the sea and in aggressive

industrial climates.

Technical specifications

Colour shades: Two shades are available:

light grey, RAL 7035 and battleship grey, RAL 7043. The surface is matt and smooth-running.

How corrosion develops

DIN defines corrosion as “the destruction of metals by chemical or electrochemical reactions with their environment”.

This “environment” can be the atmosphere,salt water or river water. The best-known example for corrosion is

rusting iron. This is a complicated chemical reaction where iron interacts with oxygen and water to form iron hydroxide hydrate.

This oxide is a solid which grows on the metal as a voluminous and porous coating as the reaction corrosion progresses and

which impairs properties such as load-bearing capacity.

Protection from corrosion

It

is estimated that corrosion causes an annual damage going in the billions (approx. 3.5% of the gross national product). To

avoid these effects and to protect steel and steel constructions, organic coating systems are applied. For these requirements,

IGP offers an extraordinary and highly effective two-layer powder varnish coating system, consisting of a corrosion-retarding

and adhesion-enhancing epoxy primer coat, the IGP-KORRO PRIMER 1002, and a weather-proof and UV-resistant powder coating such

as:

• IGP-DURA®face 52, 58, 80

• IGP-HWF 3001, highly weather-resistant

• IGP-DURA®cryl

40

• IGP-PFC 91 with “30-year weathering protection”

|

|

|

|

|

|

Future Coatings, Unit 2 The Pyramid Centre, Airport Service Road, Portsmouth, Hampshire, PO3 5SH

Telephone: 023 9269 1847 Fax: 023 9269 7479

|

|

|

|